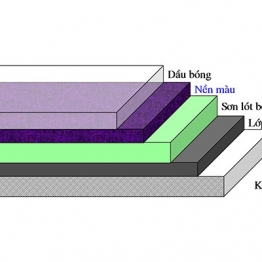

Basic components of automotive paint

When they are mixed together form a homogeneous compound. Paints are often diluted with paint for easy use. In the case of two-component paints, a hardener is added.

Once mixed, the original paint will be mixed with solvent or diluent to adjust the viscosity to suit the painting conditions.

1. Plastic resin (film-forming agent)

Plastic resin is the main component of paint, in general it is viscous and transparent liquid that produces a coating after painting onto the object to be dried.

The properties of plastic resins directly affect the properties of the coating such as hardness, resistance to the solvent and changes in weather. And affect quality such as surface underside, gloss, ease of use as well as paint drying time.

Film coatings formed after coating on the surface of the material will move from a viscous liquid to a solid state and adhering to the drying agent.

Plastic resins are polymeric organic compounds of natural or synthetic origin.

-

Plastic resin

They are extracted from plants such as varnish, lacquer, pine resin, oils such as tuna, linseed oil, soybean oil, ... or animal derived fats, which are mixed with the pigment. To make decorative and protective paints depending on the purpose of use. This plastic resin is not used in mass production.

-

Plastic sealant

Are polymeric compounds which are synthesized from the polymerization reactions of the polymerization or condensation process. Compared with natural-derived filmmakers, synthetic filmmakers have larger molecular weights, more complex chemical structures, and therefore have more superior characteristics and properties.

Synthetic resins are divided into two types, thermoplastic and thermoplastic.

-

Thermoplastics are those that are melted or transferred from a solid state to a state of melting or decomposition under the effect of high temperatures. Such as Polyethylene, Polyvinyl chloride, Polypropylene, Polystiren, ...

-

Thermoset resins are plastics that are altered by chemical reactions that undergo a process of curing or decomposition of macromolecules. Thermoset resins are commonly used as coatings for common paints such as Melamine resins, Acrylic resins, Polyester resins, etc.

2. Powder

Pigments are fine grained particles, particle sizes ranging from a few microns to tens of microns, dispersed in the paint medium and give the film its special properties. The importance of pigment is to give the film a certain color, loss of transparency, some pigments can give the film has the function and ability to work better. The pigment is evaluated by the coating, the coating depends on the opacity and the refractive index of the pigment. Depending on the function, pigments include: inorganic pigments, organic pigments, metallic pigments, auxiliary pigments.

-

Inorganic pigment

Representing this group includes colored pigments such as: ZnO (white), CdSCdSe (dark brown), PbCrO4 (yellow), Cr2O4 (green), anti-rust pigments such as Fe2O3 (red brown), PbO2.2PbO (orange), ...

-

Organic Pigments

These are pigments synthesized from organic compounds with the group of functions such as:

- N =N - , =CH-N=,…

-

Metallic powder

Metallic pigments such as aluminum powder (AL), zinc powder (Zn), lead powder (Pb), ...

-

Aauxiliary pigments

Auxiliary pigments are used as powders or fillers to improve some properties of paint film, such as Barite (BaSO4, which is a filler), Mica (K2O.2Al2O3.6SiO2.2H2O , put into paint to reduce water permeability, avoid cracking and chalking), kaolin, talc powder,...

3. Solvent

Solvent is a liquid, volatile solvent used to dissolve the film and change the viscosity of the paint. A good solvent must meet the following requirements: to create a suitable viscosity solution for storage and use, to have a reasonable cruising speed and to produce a film with optimum properties, less It affects the health and smells acceptable.

With dry chemical paints, the main task is to create a paint solution that can be painted in the most appropriate way.

With physical dry film coatings, solvents play a more complex role because not only does it affect the choice of the method of painting, but it also plays a critical role in the drying time and properties of the film. In these cases, a variety of solvents are used, each of which has its own roles. In addition, some solvents need to be added to the component during use to adjust, reduce, reduce or increase the evaporation rate of the solvent to suit the chain conditions.

Here is the evaporation point of some solvents:

- Evaporation solvent at low temperature (<100oC)

Acetone, Methyl ethyl ketone

- Evaporation medium at medium temperature (100 - 150oC)

Includes Toluene, Xylene, Butyl Acetate

- Solvent vapors at elevated temperatures (> 150°C) Butyl cellosolve, Diacetone alcohol, Solvesso 100

4. Additives

Additives are chemical compounds that are added for the purpose of catalyzing or improving certain properties of the paint. In some special cases it is used to prevent the deterioration of the film during the storage, use as well as to improve some of the environmental resistance of the film.

Depending on the intended use, additives will be added such as plasticizers, desiccants, curing agents, dispersants, color stabilizers, viscosity modifiers, autoclaves ultraviolet ray, water resistance ...

Relative News